STEEL AND CASTING

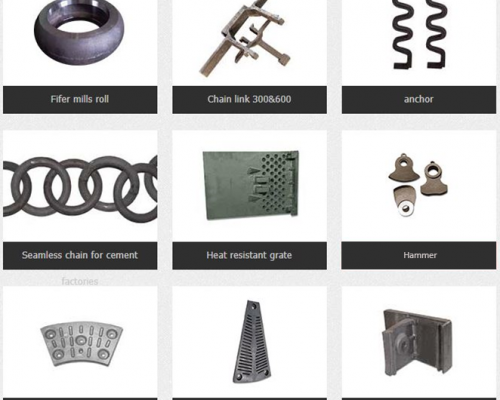

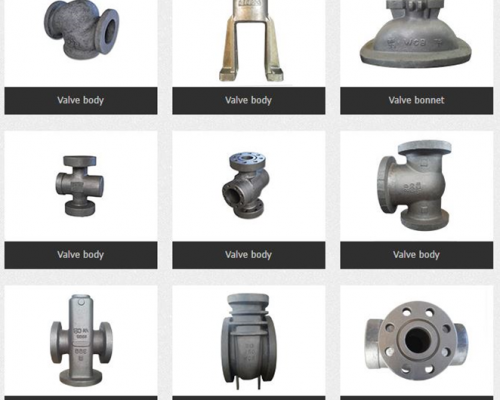

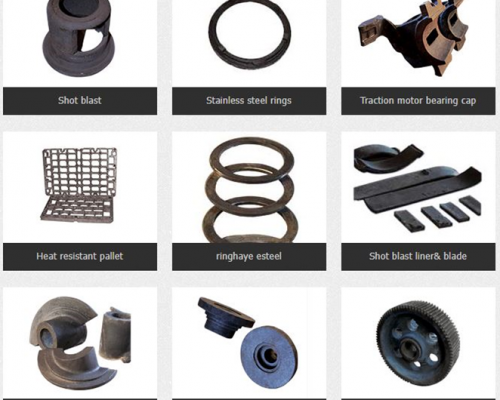

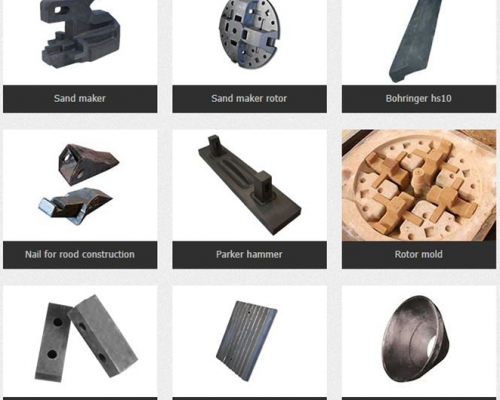

We in TACT SPOT with an expert engineering team are ready to Supply different casting parts for Oil & Gas, Mines & Road Construction, Cement, Machinery and Food industries and etc. Regarding to our Experience, we are able to Supply casting parts from 1 – 2700 Kg.

Here is a brief list of our Available equipment and services:

- Induction Furnaces: 400, 700, 2000 & 3000 Kg.

- Heat Treatment Furnaces with capacity of 2000 and 6000 Kg

- Quenching Bathes with 20 and 120 cubic meter capacity

- CO2 Molding Lines

- Quantometer, chemical analysis equipment

- Hardness test equipment

- Metallographic Microscope

- Shot Blast unit

- Finishing unit

All the managing team and engineers are graduated from good and qualified universities and the products are supplied with metallurgical knowledge and according to international standards.

Capabilities to Supply

- Casting different carbon steels, low alloy steels such as; GS, WCB, GS-CK45, 42CrMo4 (Mo40) and surface hardening steels such as; 1.7131. This group is mainly used in oil & gas, machinery and railway industries.

- Casting different kind of wear resistance cast iron and steels such as high Manganese steels (Hadfield steels) with different percentage of Manganese and Molybdenum, Ni-hard cast irons and high Chromium cast iron that are used in hammers, anvil and liners in crushers.

- Heat resistance steels that are used in high temperature application in cement, oil & gas and furnace industries, such as 1.4823, 1.4837, 1.4841, 1.4848 and etc.

- Corrosion resistance alloys such as Stainless steels casting parts (such as; 304, 304L, 316 & 316L), Ni-resist cast iron and some special alloys like Duplex steels.

- Casting modular and Gray Cast Irons according to international standards such as DIN, BS, ASTM & etc.

- We are expert in supplying produced pumps body and impellers that are used for salts and acid transferring lines and also in oil and gas industries, also we have produced casting parts with Nb, Ti, V, N & W content for many times.

STEEL AND CASTING

We in TACT SPOT with an expert engineering team are ready to Supply different casting parts for Oil & Gas, Mines & Road Construction, Cement, Machinery and Food industries and etc. Regarding to our Experience, we are able to Supply casting parts from 1 – 2700 Kg.

Here is a brief list of our Available equipment and services:

- Induction Furnaces: 400, 700, 2000 & 3000 Kg.

- Heat Treatment Furnaces with capacity of 2000 and 6000 Kg

- Quenching Bathes with 20 and 120 cubic meter capacity

- CO2 Molding Lines

- Quantometer, chemical analysis equipment

- Hardness test equipment

- Metallographic Microscope

- Shot Blast unit

- Finishing unit

All the managing team and engineers are graduated from good and qualified universities and the products are supplied with metallurgical knowledge and according to international standards.

Capabilities to Supply

- Casting different carbon steels, low alloy steels such as; GS, WCB, GS-CK45, 42CrMo4 (Mo40) and surface hardening steels such as; 1.7131. This group is mainly used in oil & gas, machinery and railway industries.

- Casting different kind of wear resistance cast iron and steels such as high Manganese steels (Hadfield steels) with different percentage of Manganese and Molybdenum, Ni-hard cast irons and high Chromium cast iron that are used in hammers, anvil and liners in crushers.

- Heat resistance steels that are used in high temperature application in cement, oil & gas and furnace industries, such as 1.4823, 1.4837, 1.4841, 1.4848 and etc.

- Corrosion resistance alloys such as Stainless steels casting parts (such as; 304, 304L, 316 & 316L), Ni-resist cast iron and some special alloys like Duplex steels.

- Casting modular and Gray Cast Irons according to international standards such as DIN, BS, ASTM & etc.

- We are expert in supplying produced pumps body and impellers that are used for salts and acid transferring lines and also in oil and gas industries, also we have produced casting parts with Nb, Ti, V, N & W content for many times.