Description

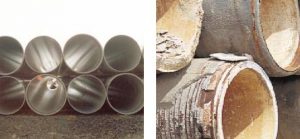

Corrosion Impervious:

Fiberglass composite pipes are being used in any industrial applications, where corrosion from the fluid the surrounding environment is the main concern and the cause of the pipeline failure.

Easy to specify:

We offer a broad range of pipes and fittings for any application and installation method such as above ground, underground, subaqueous, micro-tunneling, pipe jacking and more.

Easy to install:

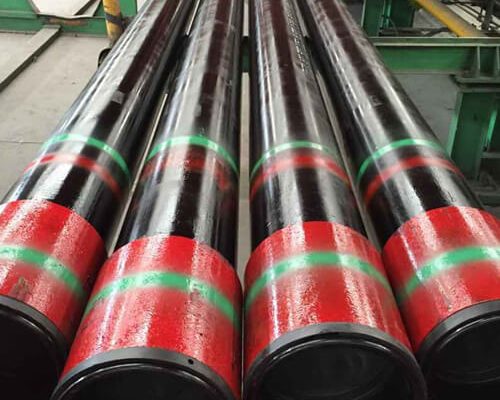

The smooth interior surface of GRP pipes cause to low fluid resistance, which could lower power requirements for pumping systems and also reduce the required diameter relative to other material. This characteristic could contribute to a substantial cost savings over the life of a typical piping system. The interior pipe surface remains smooth throughout life services, so fluid resistance does not increase with age.

Smooth inner surface:

GRP pipes are installed easily and quickly due to its light weight. These can be manufactured up to 12m long to speed up installation compare to other materials, hence transportation and installation is easier than other material. GRP pipes are light weight which cause to less expensive installation, labor and machinery cost.

Other Advantages and features of GRP and FRP PIPES:

GRP pipes are the best investment you can make in your piping project. Here is a list of cost-saving benefits and technical advantages of GRP piping systems:

- Corrosion resistance

- Lightweight

- High strength/weight ratio

- Non-toxic. Suitable for potable water

- Ease of handling

- High resistance to surge pressure

- Multipurpose material, providing the possibility to be used in countless applications and environments

- Ease and low cost of Installation

- Practically maintenance free

- Excellent hydraulic properties (smooth inner surface)

- Easy to specify for any project

- Wide range of Fitting

- Leak free joints

- High abrasion resistance

- UV resistance

- High structural load capacity

- Compatibility with other materials

Industries and applications:

GRP pipes and other composite components have been in prolonged service in numerous industries such as:

- Potable water

- Municipal Sewage disposal and raw water supply

- Desalination

- Sea-water outfalls and intakes

- Cooling network systems and geothermal lines

- Cargo and ballast lines for tankers

- Chemical processing and effluent systems

- Slurry lines

- Ducting and conduits

- Liquid food and edible products

- power plants

- Water treatment process lines

- Agriculture Irrigation systems

- Storm water

- Rehabilitation and relining of old steel or concrete pipes.

- Pipe jacking

- Micro-tunneling