Description

UPVC pipe usage

- Transportation of sewage

- Urban and industrial applications

- Pressure water supply networks

- Electrical and power network cables coverage

- Coverage of telecommunication cables

All kinds of PVC pipes

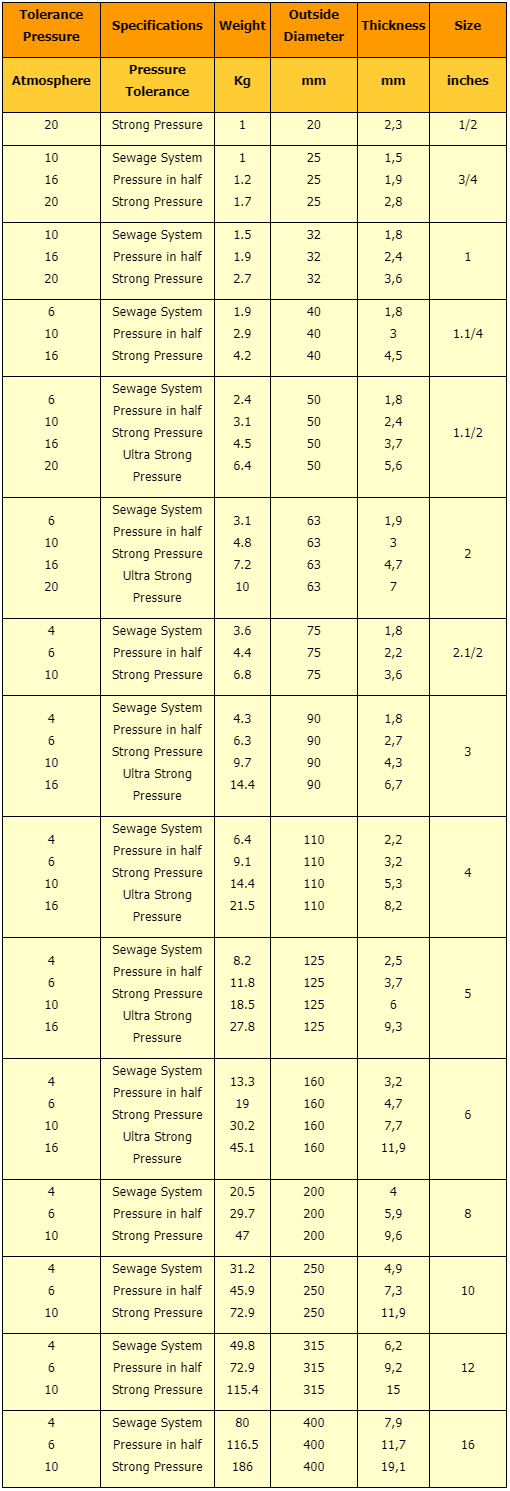

UPVC Pipes are produced in the models of felt, screw, thread, glue and wax, each of which is used according to their application. The UPVC pipes are used to transport fluids without pressure or with low pressure, and for these classes of work, common connections are used, but for high pressure fluids, it is important to use a weld joint.

PVC pipes are generally categorized into four: PVC-U unplasticised PVC), C-PVC (chlorinated PVC), PVC-O (molecular oriented PVC) and modified PVC. Besides sharing many of the same properties, each type of PVC has its own advantages for different applications.

- PVC-U

Unplasticised PVC (PVC-U) is the most common PVC type for pipes and fittings.

- C-PVC

chlorinated PVC (C-PVC) is typically used for pipes and fittings for hot and cold water.

- PVC-O

Molecularly oriented PVC (PVC-O) is typically used for pressure pipes for drinking water.

- Modified PVC (PVC-M, PVC-HI, PVC-A)

High Impact PVC (PVC-HI) is a material of choice for natural gas networks and fit for transport of hydrogen.

Properties and advantages of UPVC

- UPVC tube resistance to corrosion

UPVC pipes are resistant to electrochemical reactions caused by acids, bases and salts that lead to corrosion U-PVC pipes are resistant to UPVC applications in metals. This feature is available on the inner and outer surface of PVC pipe. As a result, the use of a tube in which the invading soil is present is very cost effective

- High chemical resistance in UPVC pipe

It is resistant to many alcohols, oils and non-aromatic oil. It is also resistant to chemicals in the soil and water against most corrosive substances such as inorganic acids, bases and PVC is resistant to salt. For typical water supply work, chemical tubes are only introduced when there are abnormal conditions or used to transfer chemicals.

- Modulus of elasticity and flexibility

The resistance of U-PVC pipes to failure is one of their important functional advantages. Under-loaded PVC can deform without fracture. The U-PVC elastic modulus is one of its most important advantages for technical applications, especially in situations where motion or soil vibration is probable (earthquake, etc.). The high level of this quantity makes it possible to minimize the duality of these pipes. Also, considering that the thickness of sewage pipes is determined based on the amount of modulus of resin elasticity used in pipe making, the high U -PVC module reduces the thickness of the tube and increases the cross-flow through the flow.

- Long tensile strength

Pipes are formulated to provide long tensile strength. Minimum required strength U-PVC pipes are about twice as large as the corresponding values of other plastic tubes, such as Poly U PVC (used in the design of pressure pipes) is less for pipes than for other plastic pipes, and ultimately weighs less, which is U-PVC is ethylene. That’s why the thickness of the pipes is an important advantage.

- Strength to high weight, light weight ratio

It has a lightweight advantage that the important U-PVC safety aspect minimizes the thickness and lightness of these tubes. U- PVC pipe has high strength. Easy transportation, minimizing work damage and facilitating cheaper installation and shipping. A person can easily carry two 6-meter pipes of 110, but can only carry less than 1.5 meters of iron pipe 110 with the same force.

- Couplings fittings

U-PVC is an important advantage for any fitting sealing pipe. Push-fit tubes with high entrance depth and oaring systems. It used the same advantage to be better than traditional products.

- Resistance to abrasion and scratch

U-PVC pipes exhibit high resistance to abrasion and scratches. PVC pipes have been proven to be much more durable than metal, cement and clay pipes for the transport of unstable materials.

- Strength of impact in UPVC pipes

Under normal circumstances, U-PVC pipes have a relatively high resistance to impact damage compared to clay pipes, cement and most common materials in pipe making. Despite the reduced impact resistance of U-PVC pipes at very low temperatures, the impact strength is still higher than required.

- Low Roughness in UPVC pipe

The roughness of the pipe is a very important and effective factor in reducing pressure and reducing the discharge. U- PVC pipe has a very low resistance to fluid flow due to its highly polished interior surfaces (low coefficient of roughness and friction). In addition, in many tubes, bacteria accumulate in rough sections of the pipe (the formation of biofilm) and close the flow of water through the flow of water, which causes a drop in the pressure and the health of drinking water which also have a negative impact. The hydraulic roughness of the U-PVC pipes by preventing the formation of biofilms, in addition to reducing the pressure drop, prevents the sedimentation of sludge in sewage networks and in drinking water distribution networks also reduces the risk of contamination. Therefore, the cost of maintaining these pipes is low and the pipeline’s design is also optimized.

- water quality

Using suitable formulation for producing U- PVC pipes, compliance with standards 62-61NSF, it can be used to transfer drinking water and ensure that lead, tin and other toxic elements such as mercury, worm, cadmium and barium are below standard limits.

- UPVC pipe resistance against flames

The U-PVC pipe hardly ignites and does not continue to burn in the absence of an external source. The spontaneous flare temperature is 454 degrees Celsius, which is much higher than most construction materials. Due to the burning of PVC, HCl gas is released, which prevents oxygen from reaching the ignited area. That’s why PVC is called a self-extinguishing agent.

- Reasonable price of UPVC pipes

In addition to the privileges mentioned for U-PVC pipes, the prices of these pipes are very Reasonable and competitive with other pipes of polymer, metal, cast iron and so on. So that U-PVC pipes in the world today are one of the main options in the water and wastewater networks.

Quality of UPVC pipes

UPVC pipes are not the same as polyethylene pipes, which can’t be added an additive, and most non-standard manufacturers add additives, known as fillers, that affect the quality of the PVC pipe, and the tube becomes brittle.

In the appearance, the UPVC tube is more fragile and drier, the standard is near standard. The standard UPVC should be soft and cannot easily crack or break with any impact. In the field of producing UPVC pipes, it is highly misleading and fraudulent, and when buying an UPVC tube, refer to the standard name, manufacturer name and standard number on the tube. Because the UPVC pipe used to cover the cable cannot be used for sewage transmission and may not have sufficient strength.