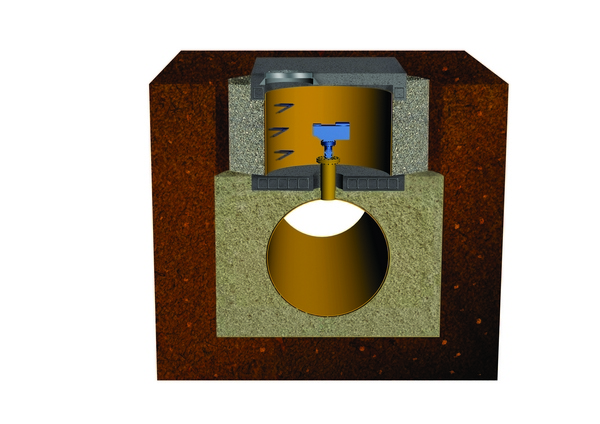

Description

Valve pits are custom made based on client’s requirements or according to international standards such as:

- ISO 9001

- 163Publication

- ASTM3753

- EN 15383

In general, when GRP pipes are installed vertically as in the case for Valve pits, external circumferential forces have a minimal effect on the pipe structure. Therefore, pipes with low stiffness class (2500 Pa) could be used to construct the pits and Valve pits even when the Valve pit is installed in depth of up to 6 meters.

Applications

- Installation and maintenance of Valves and other accessories

- Pumping stations

- Air release and breathing of the pipeline

- Redirecting the flow of fluid

- Providing access to inspect pipeline

- Cleaning the main lines

- Changing the flow condition of the fluid

Advantages of Valve pit:

Resistance to corrosion

- Durability of structure

- Reliability and stability of structure

- Minimum maintenance

- Resistant to internal and external corrosion

Low weight

- Flexibility in design and production

- Cost saving in loading, transportation and unloading

Stability through Design

- Strong by design

- Consistency in dimension

- No infiltration or ex-filtration

Ease of installation

- Fast and easy installation

- No need for costly foundation

- Minimum excavation

- Ease of manipulation of the structure after installation such as adding new branches or pieces.